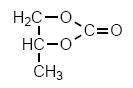

Propylene carbonate (PC) is a clear, organic polar solvent made from the reaction of propylene with carbon dioxide.

This post focuses on the use of PC in cleaning and degreasing formulations. However, there are several other recognized uses of this material in other applications.

For example, PC is prevalent in chemical intermediates, paints/coatings, dyes, fibers, as a reactive diluent in urethane systems, wood binder resins, safer alternative in cosmetic/personal care formulations, and as electrolyte solvents for lithium batteries (among many more).

Performance Characteristics

PC is used on its own and in a variety of end-use cleaning and degreasing formulations due to its versatility, effectiveness in reducing surface tension, and ability to improve wetting and soil removal functionality. Formulators also incorporate propylene carbonate into water rinsable solvent systems.

This offers a distinct advantage in VOC reduction projects. PC is also broadly compatible with other solvents, such as dimethyl esters, providing an effective ingredient in co-solvent formulations on a variety of soils, resins and substrates.

Hansen Solubility Parameters

- Total 13.3

- Dispersive 9.8

- Polar 8.8

- Hydrogen Bonding 2.0

Environmental, Health & Safety

PC is commonly used in processes and formulations to minimize toxicity and volatility concerns. It is currently listed in the Solvent category on the EPA Safer Chemicals Ingredients List for use in DfE labeled products (Indicated by the Green Circle, meaning the chemical has been verified to be of low concern based on experimental and modeled data).

Due to its low vapor pressure and findings of negligible photochemical reactivity, PC is currently considered VOC exempt by the US EPA. It is also considered a non-VOC according to EU dir 1999/13/EC.

Additional positive EHS features include a high flash point (Closed cup: 275 F°), high boiling point ( >487 F° ), and low vapor pressure (0.023 mm Hg). This material is also readily biodegradable per OECD 301B.

Because of its preferable safety and regulatory profile, PC has been a very effective substitute for traditionally used but more hazardous and heavily regulated solvents, including methylene chloride, perchloroethylene, NMP, acetone, MEK, and toluene.

Example Cleaning, Stripping and Degreasing Applications:

- Circuit board and electronic cleaners (Pure Grades)

- Polyurethane clean up

- Carburetor cleaners

- Polymer/resin clean up

- Inks and ink cleaners

- Unsaturated polyester clean up

- All purpose industrial and consumer clean up

- Stereolithography parts cleaning

Formulations and Samples

As mentioned, propylene carbonate offers an excellent VOC and toxicity reduction solution for several formulations and applications. As both a supplier and formulator of this material, we offer flexible, customized solvent systems using PC as a component or stand-alone raw material.

Contact us for more information on this product or to discuss your application and request a sample.

Receive articles and product updates by email.