Supplying dimethyl esters for over 20 years.

Highest quality, domestically sourced and competitively priced.

J R Hess Co. offer DMEs in standard and customized ratios for customers in wide range of industries.

Quick Quote

Please fill out the following form to receive a quick quote for dimethyl esters.

Frequently Asked Questions

Below are answers to some common questions about dimethyl esters and our Sta-Sol solvents, including product origins, properties, usage and disposal.

Download the FAQ guide or explore below.

If you have additional questions or concerns, please feel free to contact us.

Solvent users are usually concerned about flammability based on one or more of the following recognized definitions of flammable liquids:

- DOT Class 3 flammable liquid: applies to liquids with a flash point of not more than 141°F

- OSHA recognizes four categories of flammable liquids, with a maximum flash point of 199.4 °F

- RCRA defines ignitable waste as liquids with a flash point less than 60°C (140°F)

Dimethyl esters, whether present as mixtures or separate components, have flash points of >200 °F. Therefore, these materials are not considered flammable liquids under the above definitions.

Dimethyl esters are considered a ‘greener’ solvent for many reasons.

For example, manufacturers and government bodies often cite factors such as lower levels of toxicity, limited environmental impact, and reduced physical hazards in classifying DMEs as safer or environmentally preferable alternative solvents.

But the raw material origins of dimethyl esters are also worth mentioning.

A Recycled Material

Dimethyl esters are a byproduct of the adipic acid manufacturing process.

Adipic acid is an essential precursor to the production of nylon.

During the production process, waste streams are generated which contain different chemical byproducts, including adipic, glutaric and succinic acids.

In the absence of further chemical processing, this waste stream would be burned or otherwise disposed of, creating an additional burden on the environment.

However, scientists working for producers of adipic acid and downstream materials such as nylon 6,6 figured out that, through the process of esterification, the dibasic acid byproducts would have additional commercial utility.

Instead of burning or down-welling these materials, the waste stream is reacted with methanol to produce dimethyl esters.

This reactionary process is why trace amounts of methanol (i.e. <0.1%) are sometimes present and listed at very low percentages in dibasic ester safety information.

The esters are then separated via fractional distillation to produce distinct grades of dimethyl adipate, glutarate and succinate.

The Low Vapor Pressure exemption (LVP-VOC) applies to chemical ingredients in consumer product formulations that meet one of the following three criteria:

- Vapor pressure of < 0.1 mmHg @ 20° C;

- 12 or more carbon atoms in compound;

- >216° C boiling point

Whether treated as components or chemical mixtures, dimethyl esters may satisfy one or more of the above criteria.

For instance, dimethyl adipate satisfies both the vapor pressure (<.1 mmHg @ 20 °C) and boiling point (>216 °C) criteria. In those cases, the percent weight of DMEs in the formulation will not count towards the total VOC content calculation.

Contact us for more information.

Our Sta-Sol® products are often used in cold cleaning operations.

Boiling point is an important factor in evaluating solvents for cold cleaning processes, as it indicates how high a solvent can be heated (within your company’s safety parameters) to expedite soil removal.

While this information is present in our data sheets as distillation ranges, the following boiling points apply to the individual esters:

- Dimethyl Glutarate: 213 °C (415 °F)

- Dimethyl Adipate: 252 °C (450 °F)

- Dimethyl Succinate: 200 °C (392 °F)

Water solubility may be a key factor in your solvent selection process.

Dimethyl esters – when used on their own – are only slightly water soluble.

Solubility of DMEs in H20 ranges from 2 – 10%

Solubility of H20 in DMEs ranges from 3 – 4%.

If water rinsing or aqueous formulation is desired, we typically recommend the addition of a surfactant to aid in emulsification.

Contact us with questions or for information about Sta-Sol ME microemulsions.

Each component of dibasic esters – dimethyl glutarate, dimethyl adipate and dimethyl succinate – is recognized as a “safer chemical ingredient” by the EPA.

The EPA identified several solvents as safer chemical ingredients for use in cleaning formulations.

The safest in the solvent category were identified as being of low concern based on current data. In their alternatives assessment, the EPA evaluated commonly used cleaning solvents against key “Attributes of Concern”, including:

- Carcinogenicity

- Neurotoxicity

- Acute Mammalian

- Toxicity

- Reproductive and Developmental Toxicity

- Repeated Dose Toxicity

- Environmental Fate and Toxicity

Dimethyl esters are considered of low concern for the above attributes based on data evaluated by the EPA.

It is important to select compatible materials for any containers, seals, gaskets, etc., which may be exposed to Sta-Sol® DMEs or DME based products.

Dibasic esters are compatible with a variety of plastics and elastomers, including neoprene, silicone, and ethylene propylene polymers. Tetrafluorethylene, as well as polyolefinics including polyethylene and polypropylene, are also compatible.

Use of buna-N rubber (NBR), fluoroelastomers and polyurethane types are not recommended, as these may swell or otherwise degrade.

For an updated list of plastics and elastomers compatibility, contact us.

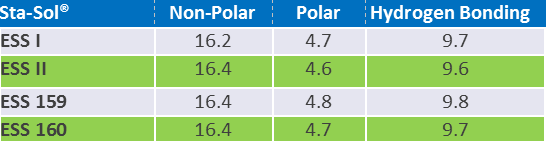

To aid in solvent selection, the HSP of solvents can be used to determine like values in soils and resins and help predict solubility. The HSP values of certain Sta-Sol® dimethyl esters are provided below.

In general, the esters share similar values with a variety of polymeric resins.

However, when the esters are included as co-solvents in mixtures containing other ingredients, the scope of resin solubility may vary widely.

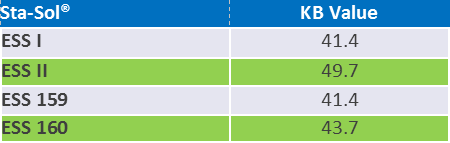

Kb value measures solvency relative to Kauri gum resin. It does not measure resin solubility of a particular solvent or solvent mixture outside of this limited test. The Kb solvency value of certain Sta-Sol® dimethyl esters is noted below:

Dimethyl esters have a suggested shelf life of two years from the date of manufacture when stored in tightly closed, compatible containers and under normal conditions of heat and humidity.

Do not leave the solvents exposed to air as they will evaporate and absorb moisture. For additional storage, handling and safety information, see SDS.

One of the advantages of using low vapor pressure, high boiling solvents like DMEs is that they can be recycled for repeated use. A splitter is typically used to separate soils and recover pure solvent.

The process can be repeated and the solvent may be reused for as long as it remains effective in your application.

If you are unable to recover pure solvent, or require virgin material in your process, the spent solvent must be disposed of in accordance with all applicable federal, state, regional and local waste disposal regulations.

Some guidelines on waste disposal:

- The waste profile of dimethyl esters may change from non-hazardous to hazardous depending on the profile of resins or other materials present in the spent solvent

- Use a licensed waste disposal contractor to dispose of any solvent waste

- Untreated waste should not be disposed of to any sewer unless fully compliant and authorized by local regulatory authorities

- Avoid dispersal of spilled material and runoff or contact with soil, waterways, drains and sewers.

- Waste packaging must also be disposed of or recycled safely

Sta-Sol® dimethyl esters are available in the following quantities:

- 16 oz. sample bottles (order)

- 5 Gallon Pails (40# net wt.)

- 55 Gallon Drums (485# net wt. / poly or steel drums)

- 275 Gallon Totes (2400# net wt.)

Bulk ordering also available. Contact us for more information.

Dimethyl esters are available in drums, totes and bulk quantities.

They are not classified as hazardous by DOT.

Contact us to request Safety Data Sheets, Samples, and Quotes: