Four Application Examples

This article highlights four key application areas where conventional solvents can be replaced with Sta-Sol® Microemulsions for safer, water-based cleaning.

Download the PDF version of this article.

Introduction

Microemulsion concentrates are flexible formulating ingredients for aqueous cleaning applications.

Listed below are four key application areas where there is great potential to improve safety*, reduce costs and enhance performance when using a water based cleaning system based on microemulsion chemistry.

Industrial Adhesive Removal

Adhesives are used in countless consumer and industrial applications for their adhering and bonding properties.

For example, polymeric adhesives are used to join components for structural, semi-structural and non-structural applications.

As adhesive technology continues to evolve, adhesive systems have become more complex and robust.

Adhesive technology is also becoming safer and more environmentally friendly in order to meet new regulatory requirements in industries such as construction, consumer products, and marine applications.

Using adhesives can be a messy process, though, and adhesive residue can be very difficult to remove from surfaces.

A strong and versatile solvent is usually required for this task.

When removing an adhesive, the solvent components will soak into the cured adhesive and transform it back into paste or liquid.

Flammable, Highly Volatile Conventional Solvents

Unfortunately, the conventional solvents used in industrial adhesive removers tend be hazardous, especially in a closed cleaning atmosphere.

Conventional solvents in adhesive removal include acetone, ethyl acetate, MEK, toluene and xylene.

With the exception of acetone, which is a volatile solvent that is exempt from VOC regulations, the above solvents are each considered VOCs per consumer products definitions.

These solvents also each present a fire hazard, as they have low flash points and are classified as flammable liquids (acetone is classified as extremely flammable).

Safer and Worker Friendly Alternatives

Using microemulsions in industrial adhesive removal allows formulators to create much safer and potentially more effective water-based products.

For example, recent testing showed that Sta-Sol ME 1100C, used “as is”, was successful in removing 100% of a polyurethane based adhesive, and 93% of an epoxy cured adhesive adhered to metal.

When formulated with co-solvents and additional ingredients, microemulsion based adhesive removers can target a broader range of adhesive systems.

Recommended co-solvents for more advanced adhesive removal formulations include DMSO, d-limonene (at low concentrations), and dibasic esters.

These co-solvents can significantly boost adhesive cleaning performance at levels of just 5 – 27%.

Certain surfactants, such as linear alcohol ethoxylates (LAE) or sulfonates, can add dispersing or solubilizing properties if necessary.

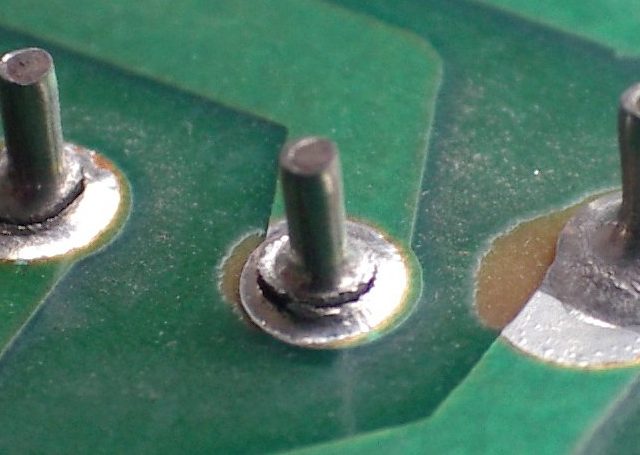

Electronics Cleaning

Cleaning solvents are used in electronics processing applications such as assembly cleaning, microelectronics fabrication, circuit board or PCB cleaning, LCD cleaning and more.

Conventional solvents used in these processes include IPA and acetone, both fast evaporating and highly flammable solvents, as well as alkaline solutions that may pose physical hazards and compatibility problems.

Microemulsions offer a solution for transitioning towards safer, water-based cleaning systems for electronics applications.

All of our microemulsions are biodegradable, non-flammable, low VOC, and non-etching.

Additionally, microemulsion concentrates also offer a pH neutral formulating alternative for maximizing compatibility and flexibility in sensitive electronics cleaning environments.

Ultrasonic and Batch Immersion

An optimal way to use microemulsions in electronics cleaning applications is through the use of ultrasonic or batch immersion cleaning processes.

Immersion processes allows for full cleaning penetration and soaking to contact and clean hidden parts and micro-components.

As an example, Sta-Sol® ME 1100C recently exceeded expectations as a replacement for acetone in an ultrasonic immersion cleaning process.

Other electronics cleaning processes where microemulsions may be used include manual bench-top and spot cleaning applications, as well as batch or inline aqueous spray-in-air processes.

Degreasing and Tar Removal Applications

Degreasing applications where conventional cleaning solvents are used include parts and machine cleaning, oilfield applications, concrete cleaning and asphalt removal, aerospace applications, vessel cleaning, automotive care products and more.

Conventional cleaning solvents used in these applications include volatile, combustible and/or flammable solvents such as d-Limonene, petroleum distillates, mineral spirits, and chlorinated solvents.

D-Limonene

D-limonene is a very effective solvent for degreasing.

However, d-limonene users face economic and regulatory challenges when using straight d-limonene for degreasing, tar and asphalt cleaning applications.

For example, d-limonene is considered ignitable for hazardous waste classification purposes (flash point less than 140°F), and flammable per DOT hazardous material definitions.

As such, using straight d-limonene increases compliance risks when handling, transporting and disposing of this material in the regular course of cleaning vehicles or other onsite maintenance operations.

For formulators of degreasers and cleaners that are subject to consumer products regulations, d-limonene is considered a VOC, making it increasingly difficult to comply with VOC limits at the state, regional and federal level.

Nevertheless, despite the known economic (i.e. drastic price fluctuations) and regulatory issues with d-limonene, this solvent can still be a very effective co-solvent in formulated solutions containing more cost-effective ingredients with better hazard profiles.

Petroleum Distillates & Mineral Spirits

Petroleum distillates and mineral spirits are also flammable liquids and considered hazardous for waste disposal.

Those who use solvents such as straight diesel fuel to clean trucks, for example, face significant compliance risks when applying these solvents onsite, as run off or spray from cleaning may now become a violation of hazardous waste disposal laws.

Chlorinated Solvents

It is well known that, while they are very effective cleaning solvents in certain applications, chlorinated solvents such as methylene chloride present many safety and toxicity issues, including demonstrated carcinogenicity.

As a result, methylene chloride is subject to strict regulatory standards, such as OSHA’s monitoring requirements.

Microemulsion Alternatives for Degreasing

Microemulsions are very effective degreasing agents.

For example, microemulsion based formulations have proven to be powerful degreasers in aqueous parts cleaning systems for removing machinery fluids and other stubborn contaminants.

These solutions incorporate powerful solvents, such as benzyl alcohol and dibasic esters, and emulsifiers.

Microemulsion concentrates may be diluted with water or extended with co-solvents and other performance enhancing components.

Possible co-solvents for effective degreasing formulations include soy methyl esters and d-limonene.

As for safety, each Sta-Sol® microemulsion is non-flammable (flash point > 200°F) and has a very low vapor pressure (< .03mmHg @ 20°C).

As a slow evaporating concentrate, a microemulsion can provide a longer lasting and cost-effective alternative for degreasing applications.

Pulp and Paper Processing

Solvents are used in pulp and paper applications for press felt cleaning and conditioning.

Conventional solvents and cleaning agents used to clean and condition press felt materials include mineral spirits, NaOH or KOH, and acidic formulations.

Water based cleaning agents are also used in Deinking applications to remove printing ink from recycled paper to make deinked pulp.

Concerns About Conventional Cleaning Agents in Pulp & Paper Processing

In addition to the physical hazardous of highly caustic or acid based formulations, there is typically concern about the shorter belt life, increased downtime and overall costs due to the deteriorating effects of harsh cleaning agents.

Mineral spirits, while a low cost option, will increase safety and compliance risks due to flammability.

Microemulsions for Paper Applications

Microemulsions have been incorporated into highly effective press felt cleaning formulations.

These products provide a pH neutral solution that can improve dewatering, enhance conditioning, extend belt life and reduce downtime.

The physical and environmental characteristics of microemulsion based cleaners are a significant improvement.

Additionally, microemulsion based pulp and paper solutions can be formulated without nonylphenol ethoxylates (NPEs) to reduce compliance concerns related to biodegradability and aquatic toxicity.

However, when used on their own, microemulsions may produce too much foam for certain paper processing facilities.

Therefore, when formulating a press felt cleaning solution, it is recommended to add a suitable defoamer.

Deinking Applications

Our microemulsion chemistry has also shown excellent potential in deinking applications.

In particular, Sta-Sol® ME 1120, a fully formulated microemulsion concentrate that is water dilutable from 0 – 70%, can significantly improve ink extraction as evidenced by ink precipitation in recent deinking testing.

Conclusion

The above examples are just a few of the emerging application areas where microemulsion chemistry may offer a safer and potentially more effective alternative to conventional solvents.

If you are interested in learning more, please feel free to send us a note.

You may also download our brochure or request a sample for testing.

——————————————————–

*References:

Environmental, Health and Safety Attributes of Sta-Sol® Microemulsions:

- Biodegradable (Source: According to OECD definition, using empirical data, and results from EPI Suite modeling software)

- Not considered VOCs in the EU, US, Canada and California (Source: EU Solvent Emissions Directive 1999/13/EC, US VOC Exemption for Consumer Products, 40 CFR 59.203(f)(1), Environment Canada’s “Guidelines For Volatile Organic Compounds in Consumer Products”, Section 95408(a)(80) of Title 17 of the California Code of Regulations.

- Non Flammable (Source: According to 2.6 of Globally Harmonized System of Classification and Labeling of Chemicals (GHS))

- Not a Hazardous Air Pollutant (US Clean Air Act)

- Not listed as ozone depleting substance (Reference: UNEP – The Montreal Protocol on Substances That Deplete the Ozone Layer)

- Not listed as carcinogens (Source: According to NTP, IARC, ACGIH, EU Dangerous Substances Directive (67/549/EEC) – Annex 1, and California Proposition 65)

- NPE Free Alkyphenol ethoxylates are not intentionally added as ingredients in the manufacture of these products.